User not logged in.

WE ARE THE QUALIFIED INSPECTORS OF FACTORIES & EACH OF THE SLABS, TILES, PATTERNS AND ENGINEERED STONE SURFACES PRODUCED FOR OUR CLIENTS.

With a management system based on ISO 9001, it is aimed at continuous improvement in all areas of our business to make certain of the satisfaction of our all Clients through the precious sense of duty of our own people. The Quality and Environmental Policy is based on offering the maximum level of content of its stakeholders, by following sustainable development values and business ethics in the development of its activity.

Please download and check our Quality & Environmental Policy here.

The implementations of rigorous total quality management principles guarantee the highest quality of the materials and manufacturing processes applied in accordance with the ISO 9001 certification.

We intend to find the most attractive natural stone selections and their point-of-origin quarries in the extractive basins of the world and become mutually reliable partners for long terms with those companies which own them and in addition; with our supply chain model of building partnerships strictly and only with quarry+factory owner suppliers, we guarantee our Clients a high and constant quality of the materials and steady characteristics of products introduced, that all will be used for the realization of their projects through their orders.

To ensure this aim, all materials are subjected to strict control of our own organization specialists in addition to the already existing control mechanisms of related point-of-origin supplier partners to verify compliance with the certain quality standards established by our expertise.

GRANITANIA MEANS TRUST FOR VERIFICATION ON EACH MATERIAL & PROCESS.

In these factories of our point-of-origin supplier partners, our Quality Assurance & Control and Supply Chain Management Departments’ professionals simply do not compromise on our certain disciplines for “Meticulous Control of Material and Monitoring of Each Process For Every Single Procurement Operation At Related Sites & Facilities” beginning with identifying and classification, continuing through cutting, calibrating, filling, curing, finishing, dimensioning, packaging, loading and ending with shipment operations for granites, marbles, travertines, limestones, quartzites, sandstones, soapstones, slatestones, tra-onyx, onyx and other natural stones besides a wide selection of engineered stone surfaces and other manufactured products all with various finishes as polished, honed, aged, satin, flamed, bush-hammered, sand-blasted, etc., in addition to the regular quality assurance & control operations of our related supplier partners’ staff.

This is the only way to make sure that we know the products we supply to our Clients are extracted, processed, finished, packed and loaded all under our control regarding all qualifications of material and processes at each operation step. This is the only way for us to achieve what we do best; Trust For Verification.

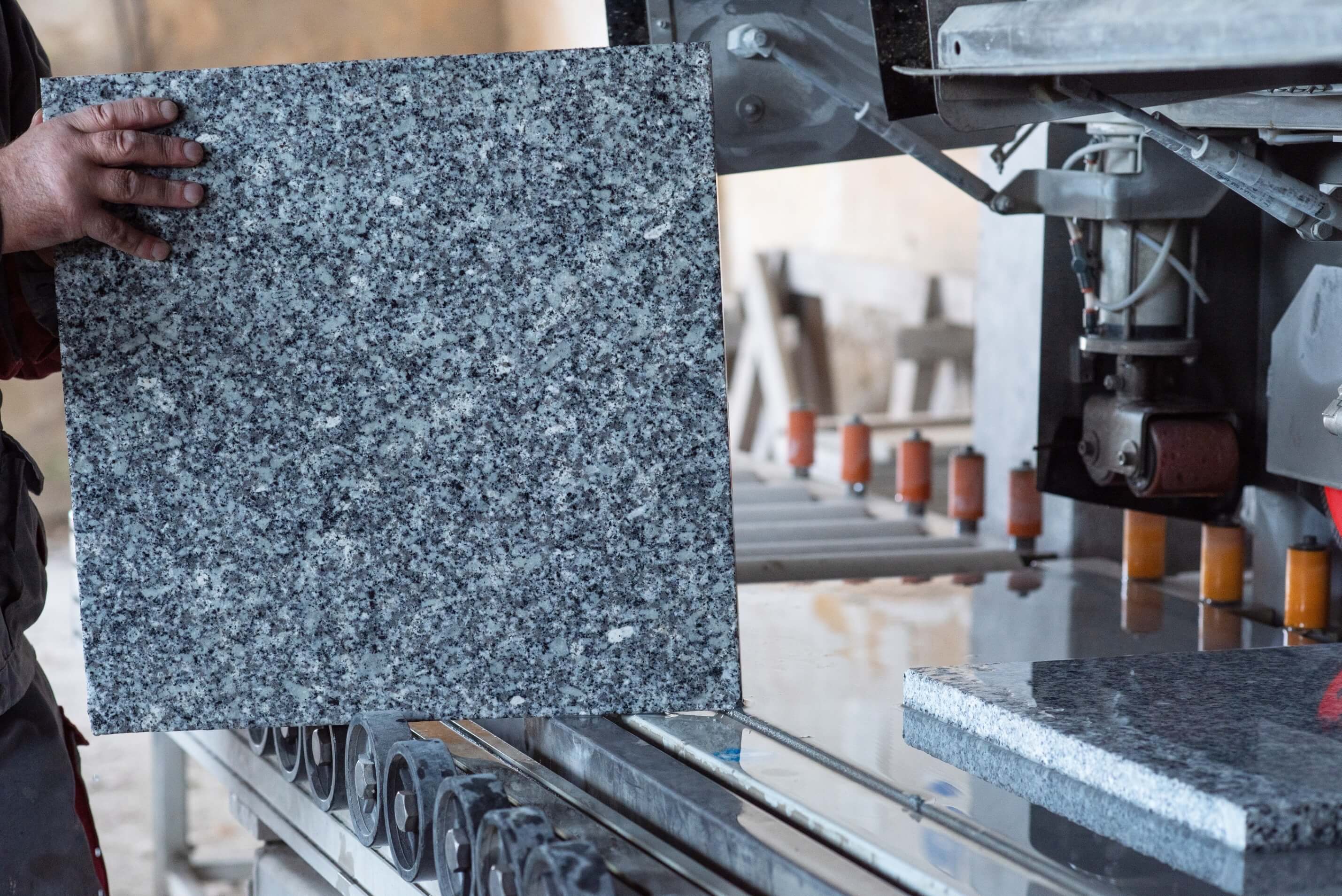

Inspector checks the block while being taken into cutting to make sure of that it is the same block selected and approved by him before.

Decision on the classification by identifying each of the slabs, tiles, patterns and engineered stone surfaces, wheter he/she agrees or not with the classification done by the factory.

Sometimes we find defects that the supplier partners offer to lower the price of the material regarding or we insist for the replacement of the right class product, which at the end results in better price or replacements absolutely with the condition of that the subject materials are qualified and the decision is approved with the consensus of our Clients.

When we have this experience, generally we catch some thin lines, small concentration or color variation that cannot be noted on the photos.

According to our procedures, the inspection of each product is to be done one by one at the end of the production line just before the operation of packing the products into the bundles and crates.

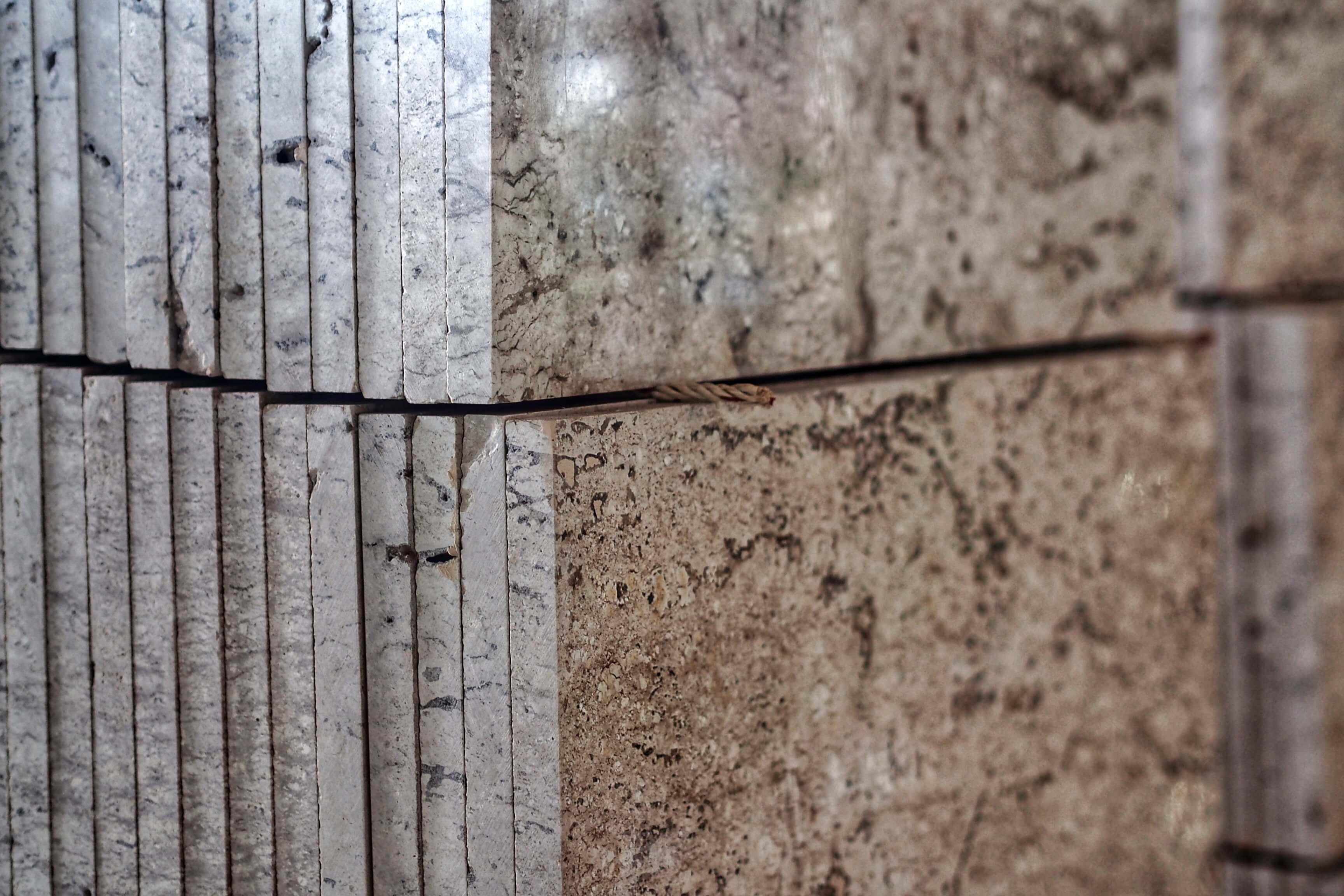

However, regarding some possible reasons which might happen in confliction with our this critical principle; like production and packing could be completed during night shift or like somehow the products could be manufactured and packed earlier than the agreed calender day etc.; then, the the bundles and crates are opened one by one again by our related supplier partners at their facilities to let our quality assurance & control engineers and technicians see the products inside their packing to make the inspection as exactly required; which means the quality check of each product is to be done one by one anyway.

Measurement corrections of natural stone slabs, tiles, patterns and engineered stone surfaces, primarily for the slabs, are very important in the stone industry.

Half inches can seem like a small difference on the amount of a single invoice, but when calculated over the containers shipped during the year, possible to lose a lot of money because of the wrong measurements.

We also pay a specific attention to fissures that should be discounted and the broken corners at each material no matter what the class and price of the material is.

Checking flatness, that is making sure especially for the slabs, besides; tiles, patterns and of course the engineered stone surfaces are not warped.

Checking polishing quality of the corners and edges to make sure they are all well polished, especially for natural stone slabs and engineered stone slabs.

Checking surface finishings types and quality of all the slabs, tiles, patterns and engineered stone surfaces to make sure they are all well finished.

Checking for structural problems, such as fissures, pit holes, saw marks, blade marks, wire marks, polishing marks, finishing defects and others which could name the product imperfect.

Taking photos of slabs and close view of each of the slabs of natural stones and engineered stone surfaces, and taking photos of tiles, patterns & cut-to-size with the required frequency for related reports and archieves in addition to our certain discipline of applicating the quality inspection of each product to be done one by one.

Complete The Inspection Report with all required informations and visuals regarding each of the products subject to the procurement project.

Get the signature of the factory manager and/or the sales people of our supplier partner on the report. It assures they are in accordance with the inspection.

A copy of the report is to the factory, so; they have a record for future reference if a claim is placed.

This part is done at our related office right after we complete our final controls on all the details of The Inspection Report and all visuals together with the required export documentations as packing list and commercial invoice and all other paperworks.

If necessary, we request correction. After all is correct, an email with The Inspection Report, photos and all required documents are sent to our related Client, requesting booking and other operations.

Granitania has an extensive global presence thanks to its great people in own offices in different countries and of course with the important support of hardworking and self...

Granitania has meticulous and detailed procedures applied in accordance with the ISO 9001 certification for quality assurance & control regarding all details of its own and also all of its...

Granitania has a strong logistics service managing many deliveries per year in different means of transport to many locations for its Clients all over the world. If you need competi...

Granitania Foundation is a non-profit organization, an expression of Granitania Group’s Organization Social Responsibility and in particular its commitment to the improvement...

Health and Safety is the leading one among the fundamentals of Granitania’s mission. It is a must for our organization to make sure the required Health & Safety regulations, qualifications and...

Granitania’s commitment to the environment is based on the fundamental pillars of sustainable development and business ethics, covering the whole product lifecycle. In the area of sustain...

Innovation is a key element in processes and product development strategies realized in Granitania’s cooperations with its supplier partners and is the main factor that leads all...

We know that our Clients’ trust in our brand is the future of our organization. Considering the heavy responsibilities we are taking as Granitania by providing to our Clients all these solid warran....

Find out news about Granitania and The World of Natural Stones & Engineered Stone Surfaces, new products, events, social activities, meetings, workshops, improvements & developments...

Granitania is focused to be a game-changer in the quarrying, processing & production and marketing of natural stones and engineered stone surfaces. It is in the process of having global...

As Granitania People, we are at your service to answer any questions you have on our organization, products and services regarding as sourcing, distributions, installations...

These website disclaimers incorporate a copyright notice asserting ownership of the website copyright, a set of exclusions and limitations of liability (ie disclaimers) and...